How do Single & Two-Stage Compressors Work Differently?

Reciprocating air compressors supports various industries and daily tasks. The power tools help the workshop and maintain production work consistently. If you need a reciprocating air compressor, you can usually choose between two main models. These include the single stage compressor and the two stage compressor. Both look similar and use a piston to increase air pressure, but they operate differently and handle workloads in distinct ways. In this blog, let’s discuss the key difference, advantages, application and efficiency of both the single stage and two stage reciprocating air compressors that help in effective choice.

What is a Single-Stage Reciprocating Air Compressor?

A single stage-reciprocating air compressor compresses the air in one stroke. It consists of the piston, cylinder, and crankshaft. The piston moves downward to bring the air into the cylinder and moves upward to compress the air to the required pressure. Once compressed, the air is stored in a tank and then used.Single-stage compressors are simple, easy to service and affordable. They are perfect for applications with moderate pressure and intermittent use.

Features of the Single-Stage Reciprocating Air Compressors

- Compresses air in a single stroke.

- Produces pressure up to 150 PSI.

- Tiny, lightweight, and portable.

- Low initial cost and easy maintenance.

- Suitable for small workshops, car repairs, and home projects.

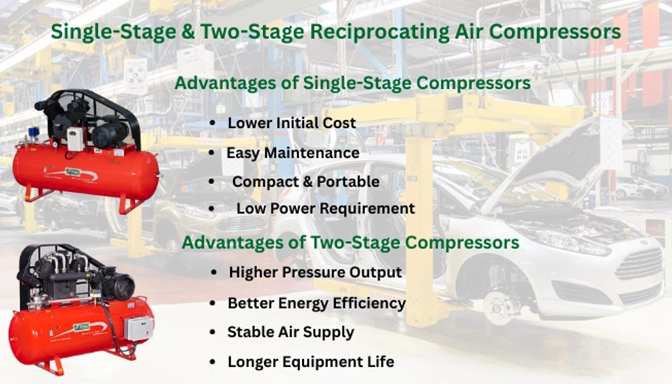

Advantages of Single-Stage Compressors:

- Cost-effective

- Simple maintenance

- Compact design

- Sufficient for light-duty work

What is a Two-stage Reciprocating Air Compressor?

A two-stage reciprocating air compressor compresses air in two steps in the process of getting high pressure. The air enters at the low-pressure cylinder, where it is partly compressed. Then it moves into a high-pressure cylinder for additional compression before entering the storage tank.

This two-step design makes the compressor more efficient and effective, especially for continuous or heavy-duty applications. Two-stage air compressors are commonly found in industries, factories, and large-scale workshops, where a steady high pressure is needed.

Features of Two-Stage Reciprocating Air Compressor:

Advantages of Two-Stage Compressors:

Comparison Table Between Single-Stage & Two-Stage Reciprocating Air Compressors

| Feature | Single Stage Compressor | Two-Stage Compressor |

|---|---|---|

| Compression Steps | One step of compression | Two steps of compression with cooling between steps |

| Pressure Level | Moderate pressure for light and medium-duty tools | High pressure for heavy and continuous duty tools |

| Workload Strength | Supports short tasks and on-and-off use | Supports long hours and heavy machinery |

| Heat Control | Builds more heat since air compresses in one step | Stays cooler because the air cools between the two steps |

| Energy Performance | Uses more energy during heavy work | Uses energy more wisely during long duty cycles |

| Cost | Lower cost and simple structure | Higher cost with stronger performance and longer life |

| Users | Home workshops and small garages | Industries and production units |

| Lifespan | Suitable for limited use | Longer life under continuous operation |

Applications: Where Each Compressor Excels

Single-Stage Applications:

- Home garages for inflating tyres and small tools

- Small automotive repair shops

- Light woodworking or DIY projects

- Painting or finishing small surfaces

Two-Stage Applications

- Factories and manufacturing units

- Large workshops with high demand pneumatic tools

- Continuous painting or sandblasting operation,

- Industrial machinery needs continuous high-pressure air.

Maintenance & Cost Consideration

Single-stage compressors use fewer parts, so you can maintain the minimum effort and lower cost. Such standard parts like pistons, valves and crankshafts are easy to replace and widely available. The two-stage compressors are more expensive initially, yet they provide efficient and longer working life. They require regular care of the intercooler and high-pressure cylinder to maintain constant performance. Even with the higher initial price, they offer better energy consumption and cost of operation in long-term industrial operation.

Selecting the Right Compressor

When choosing between single-stage and two-stage compressors, it can consider:

Pressure Requirements

- Use a single-stage for low pressure

- Use a two-stage process for high pressure.

Frequency of use

- Single-stage is applicable for intermittent work

- Two-stage is ideal for continuous operation.

Budget

- Single-stage is a low-cost work for light-duty work.

- Two-stage is a long-term investment in heavy-duty work.

Space Availability

- Single-stage does not take much space

- Two stages need a large space due to their size.

Choose the Best Reciprocating Air Compressor for Your Industry

Selecting the right reciprocating air compressor can greatly influence the efficiency, prices, and output of your task. There are some powerful advantages of both the single-stage and the two-stage reciprocating air compressors. The correct choice depends on your pressure needs, working load, and daily use. A single-stage compressor supports light and medium operations with ease. A two-stage compressor provides high-performance for demanding industrial work and long running hours. As a leading air compressor manufacturer and a supplier in Coimbatore Frank Compressors offers effective reciprocating air compressors that support steady functions across all applications.

Recent Blogs

-

How Energy-Efficient Compressors Cut Industrial Power Costs

-

Single vs Two-Stage Reciprocating Air Compressor Overview

-

Top 10 Air Compressor Manufacturers in Coimbatore

-

Air Compressors for Electronics & Semiconductor Industry

-

Smart Air Compressors with IIoT & Remote Monitoring

-

Understanding Oil-Free Scroll Air Compressors & Advantages

-

Oil-Free vs Oil-Injected Compressors for Textile Industry

-

The Role of Medical Air Compressors in Modern Healthcare

-

Tips to Pick The Best High-Pressure Compressor For Business

-

Key Things to Check Before Installing a PET Air Compressor

-

Full Guide For How Diesel-Powered Screw Compressors Work

-

Benefits of Dual-Stage and Single-Stage Air Compressors

-

How to Silence an Air Compressor for a Peaceful Workspace?

-

Expert Tips to Select Screw Air Compressor For Packaging

-

Benefits of Oil-Free Air Compressors For Food & Beverage Safety

-

The Importance of Refrigeration Air Dryers in Pharma Production

-

Why Choose a Permanent Magnetic Energy Saving Compressor

-

Industrial Diesel-Driven Screw Compressors For Remote Locations

-

The Importance of Air Compressors in Laser Cutting Machines

-

How Dental Air Compressors Benefit the Medical Sector

-

Key Applications and Benefits of Piston Vacuum Pumps in Industry

-

Understanding The Role of Air Dryers in Compressed Air System

-

Why Choose Rotary Screw Air Compressors: Essential Advantages

-

Innovative Design Features of Screw Compressors with VFD

-

Which One to Choose: Piston Vacuum Pumps vs Rotary Vane Vacuum Pumps?

-

A Step By Step Guide For Air Compressor Installation & Setup

-

Tips For Improve Your Compressor Life Span

-

Different Types Of Compressors And Their Uses In Industries

-

High-Pressure Air Compressors: Uses and Advantages for Industrial Solutions

-

How Air Compressors Are Transforming The Textile Industry ?

-

Tips For Prolonging Your Air Compressor’s Lifespan